Stage 3.5

1. Technology of texturing through laser ablation of the plane tribomodels

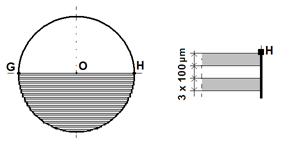

The texturing of plane surfaces for tribological purposes implies the producing of 3D geometrical modifications at the plane surface of mechanical parts with the goal of reducing friction and/or wear, when these function as base components in couples with plane sliding. When the main instrument of the texturing is a laser beam, then we have laser texturing. The principal phenomena which stays at the basis of laser texturing is laser ablation. The proposed technology has as objective the realization of textured surfaces presented in Fig.1.

|

|

Figure 1. Plane face of the grooved

surface

|

2. Technology of analysis of the textured tribomodels through electronic microscopy

In the frame of the second objective, stages are established, the conditions and the working manner - necessary for the examination through electronic microscopy of the metallic parts textured by laser beam.

The examination can be realized on any electronic microscope; the present methodology comprises the steps described for the realization of the analysis at the electronic microscope Quanta Inspect F, with a dispersive spectrometer in energy (EDS)

3. The technology for the testing of textured slider bearings

In the frame of the third proposed objective for this stage, the technology for testing of slider bearings was established.

In order to control the process of texturing which is realized on cylindrical surfaces, the bearing bushings with textured surfaces are composed by two bearing half shells. The testing of these types of bearings is realized after mounting the bearing shells in a bush device, aiming the functioning similarly to a bush with two lobes.

Another objective proposed for this stage was the verification of a temperature line and of a pressure transducer necessary for the preparation of the testing installation in view of the experiments. The results are presented in annexes, in the measuring bulletins emmited in the metrology laboratory.